Pickling

Stainless steel can corrode in service if there is contamination on the surface or if there has been a process that has altered the composition of the surface, usually welding or some other heating process. Unless a fabricator is meticulous with his/her handling of stainless steel, pickling should always be carried out after fabrication for maximum corrosion resistance.

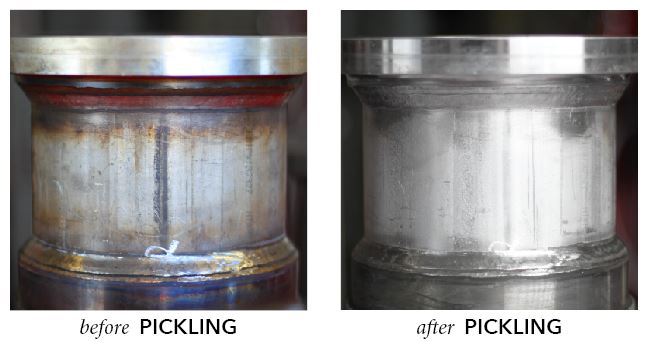

Pickling or acid cleaning restores the corrosion resistance of the surface by removing any surface contamination such as grease or dirt, as well as any embedded iron or exposed inclusion particles in the steel. The most common solutions contain nitric acid, although others are available. Some of the surface contaminants may be removed by grinding or polishing, but sometimes particles of polishing compounds can be embedded in the surface, and hence damage corrosion resistance.

Where welding or any other means, to the point where a colored oxide layer can be seen, has heated the steel, there is a chromium-depleted layer on the surface of the steel underneath the oxide layer. The lower chromium content gives lower corrosion resistance. The layer can be ground off, but it is safer to pickle it off. Hydrofluoric acid must be included in the pickling solution, since nitric acid alone will not dissolve the surface layer. Pickling is best done by immersion in the pickling solution or by using pastes where the solution is mixed with an inert carrier to allow selected areas to be treated.

If you would like to evaluate our Passivation or Pickling capabilities, we will be happy to process samples of a reasonable size and quantity at no charge.

Stainless steel can corrode in service if there is contamination on the surface or if there has been a process that has altered the composition of the surface, usually welding or some other heating process. Unless a fabricator is meticulous with his/her handling of stainless steel, pickling should always be carried out after fabrication for maximum corrosion resistance.

Pickling or acid cleaning restores the corrosion resistance of the surface by removing any surface contamination such as grease or dirt, as well as any embedded iron or exposed inclusion particles in the steel. The most common solutions contain nitric acid, although others are available. Some of the surface contaminants may be removed by grinding or polishing, but sometimes particles of polishing compounds can be embedded in the surface, and hence damage corrosion resistance.

Where welding or any other means, to the point where a colored oxide layer can be seen, has heated the steel, there is a chromium-depleted layer on the surface of the steel underneath the oxide layer. The lower chromium content gives lower corrosion resistance. The layer can be ground off, but it is safer to pickle it off. Hydrofluoric acid must be included in the pickling solution, since nitric acid alone will not dissolve the surface layer. Pickling is best done by immersion in the pickling solution or by using pastes where the solution is mixed with an inert carrier to allow selected areas to be treated.

If you would like to evaluate our Passivation or Pickling capabilities, we will be happy to process samples of a reasonable size and quantity at no charge.

Passivation:

Passivation is the treatment of stainless steel in a nitric acid or citric acid solution to remove iron contamination on the surface. The contamination is from fabrication such as stamping, drilling, machining, welding, cutting, forming or wire brushing.

Passivation does not change the appearance of the stainless. If the stainless has been heat treated or welded, the resultant scale or discoloration must be removed by either abrasive methods or by pickling. The processor must know the alloy of stainless steel before passivation is attempted so that the proper solution will be used.

Salt spray or humidity testing as well as copper sulfate testing accomplish testing to verify the effectiveness of the passivation treatment.

Passivation is the treatment of stainless steel in a nitric acid or citric acid solution to remove iron contamination on the surface. The contamination is from fabrication such as stamping, drilling, machining, welding, cutting, forming or wire brushing.

Passivation does not change the appearance of the stainless. If the stainless has been heat treated or welded, the resultant scale or discoloration must be removed by either abrasive methods or by pickling. The processor must know the alloy of stainless steel before passivation is attempted so that the proper solution will be used.

Salt spray or humidity testing as well as copper sulfate testing accomplish testing to verify the effectiveness of the passivation treatment.